Excellent Properties of Nomex® 410 Enable Long-term Reliability

Article | August 1, 2013

DuPont™ Nomex® 410, the original form of Nomex® brand paper, is widely used in a majority of electrical equipment applications. That’s because the properties of Nomex® 410 make it an ideal choice for virtually every known electrical sheet insulation application.

The excellent properties of Nomex® 410, which include high inherent dielectric strength, mechanical toughness, thermal stability, flexibility and resilience, is a standard by which all other insulating materials are compared.

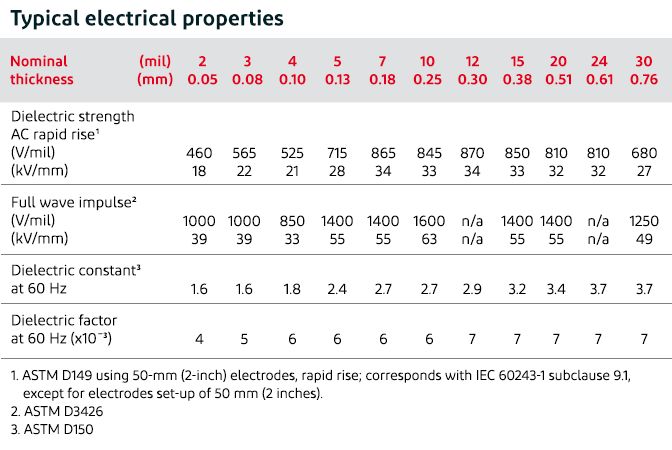

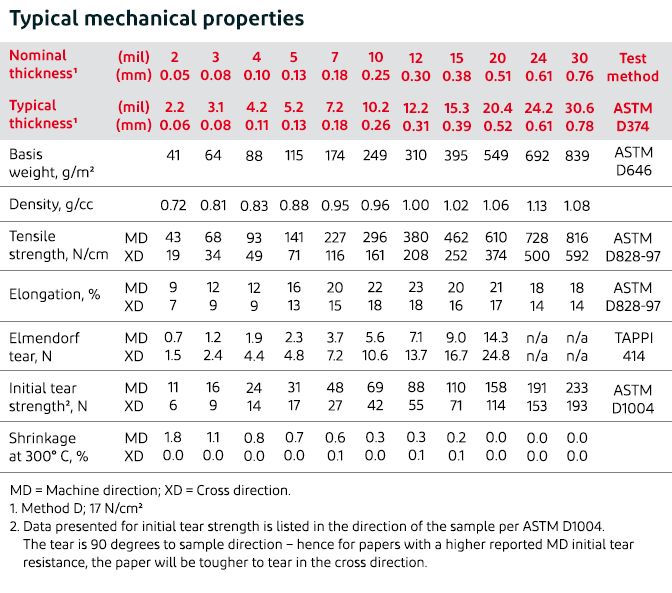

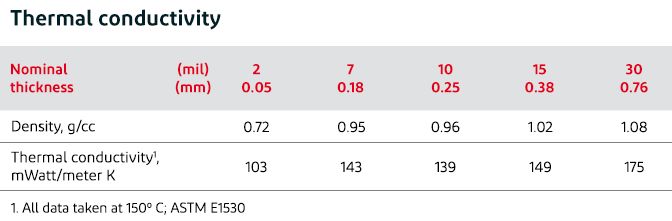

Nomex® 410 is available in 11 thicknesses, ranging from 0.05 mm to 0.76 mm

(2 mil to 30 mil), with specific gravities ranging from 0.72 g/cm2 to 1.1 g/cm2. As is true for all electrical insulating materials, thickness and density have an effect on the typical electrical, mechanical and thermal properties of Nomex® 410. Therefore, tables shown here of the typical properties of Nomex® 410 provide values for each available thickness and corresponding density.

Typical Electrical Properties

Nomex® 410 withstands short-term electrical stresses of 18 kV/mm to 34 kV/mm (460 V/mil to 870 V/mil), depending on thickness. These values differ from long-term strength potential. DuPont suggests that continuous stresses in transformers not exceed 1.6 kV/mm (40 V/mil) to help minimize the risk of partial discharges (corona).

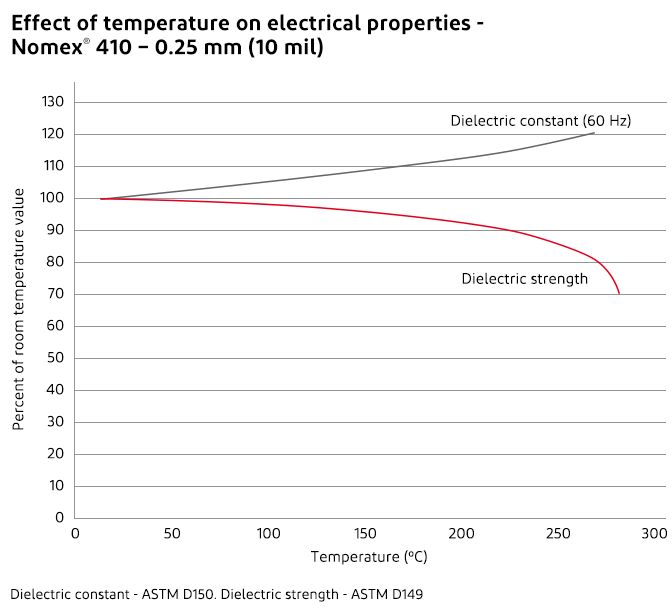

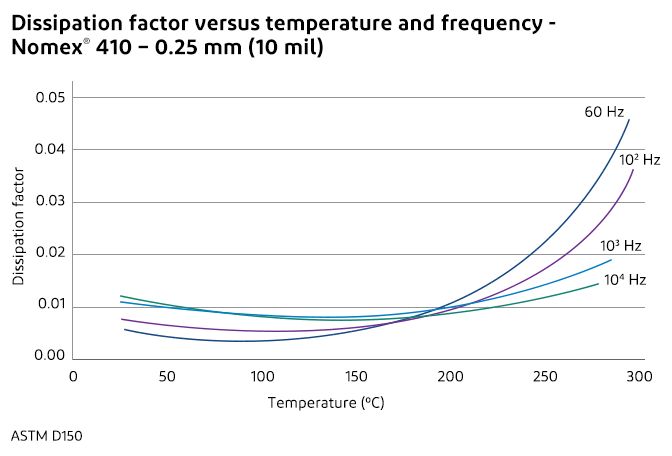

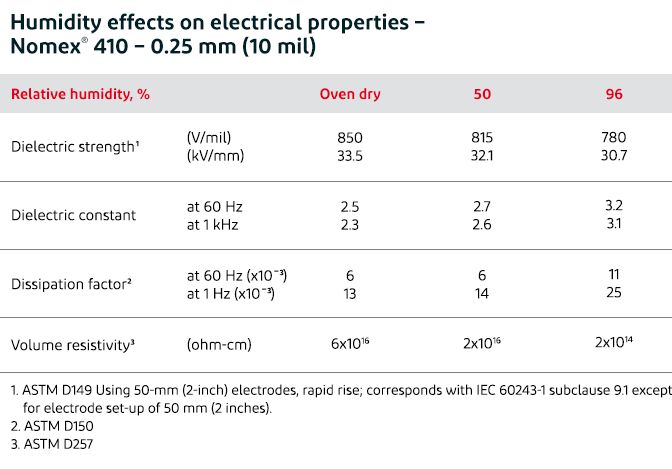

Effect of Temperature, Frequency and Humidity on Electrical Properties

Within normal-use temperatures, temperature has only a minor effect on the dielectric strength and dielectric constant of Nomex® 410.

Variations in frequency up to 104 Hz have essentially no effect on the dielectric constant of Nomex® 410.

Humidity has a relatively minor effect on the electrical properties of Nomex® 410.

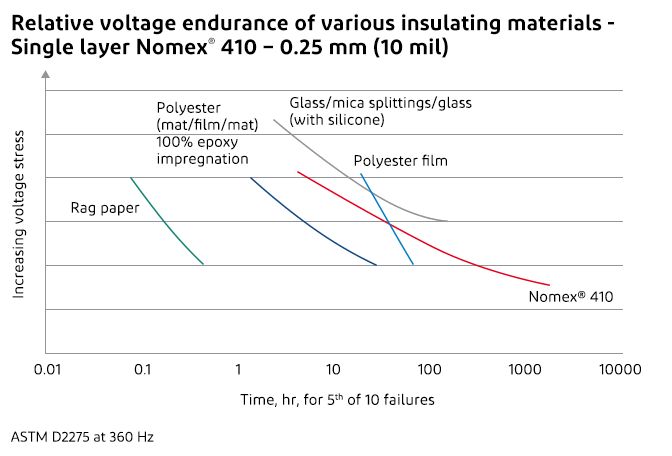

Effect of Corona

Like other organic insulating materials, Nomex® paper is gradually eroded under attack by corona discharges. Corona intensity is a function of voltage stress, which, in turn, depends almost entirely on design parameters such as spacing between circuit elements, smooth vs. sharp contours, etc.

Although corona does not occur during normal operation of properly designed electrical equipment, any device may be subject to occasional over-voltages that produce brief corona discharges. It is important that the insulation not fail prematurely under these conditions.

The voltage endurance, or time to failure under corona attack, of Nomex® 410 is superior to that of other commonly used organic insulations and even compares favorably with some inorganic compositions.

Typical Mechanical Properties

Densified Nomex® products are strong, resilient and (in the thinner grades) flexible, with good resistance to tearing and abrasion.

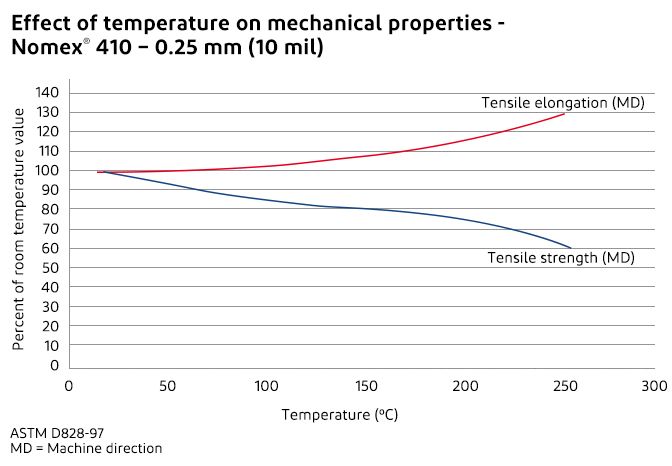

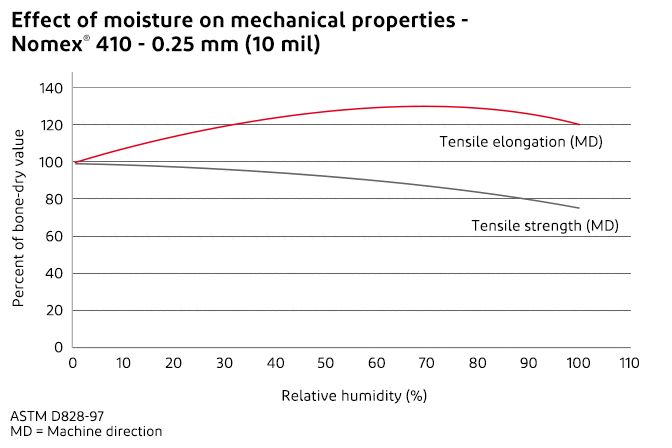

Effect of Temperature and Humidity on Mechanical Properties

Elevated temperatures have only a minor effect on the tensile strength and elongation of Nomex® 410.

At very low temperatures, Nomex® paper also retains good mechanical properties. At the boiling point of liquid nitrogen (77 K), the tensile strength of Nomex® 410 (0.25 mm [10 mil]) exceeds its room temperature value by 30% to 60%, depending on direction, while elongation to break is still greater than 3%, which is better than most inorganic materials at room temperature. This allows Nomex® 410 to work well in cryogenic applications.

Although humidity has a minor negative effect on the tensile strength of Nomex® 410, elongation, tear strength and toughness are all improved at higher moisture contents.

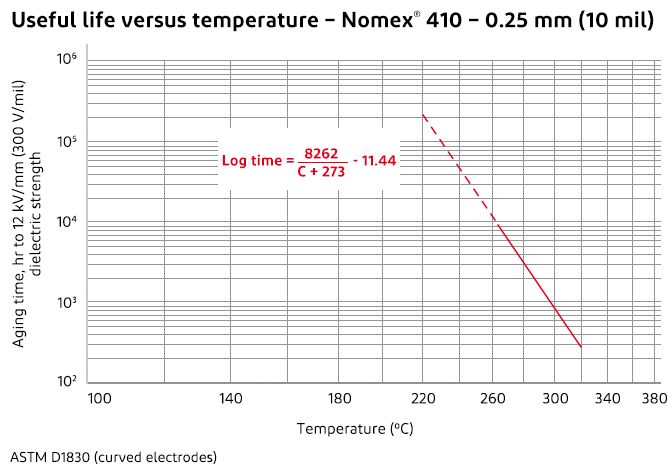

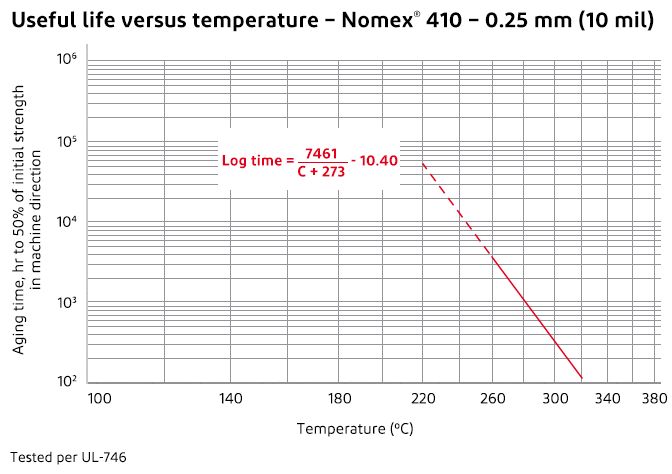

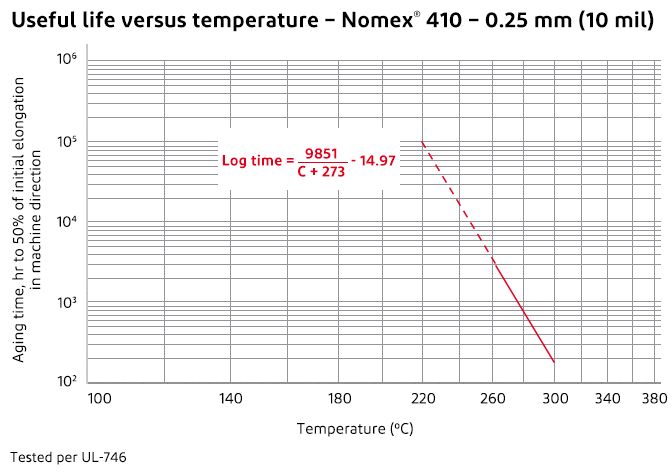

Thermal Properties

Arrhenius plots of aging behavior provide the basis for recognition of Nomex® paper as a 220°C insulation by Underwriters Laboratories (UL) and other certifying bodies. These curves can also be extrapolated to higher temperatures. For example, measurements show that Nomex® 410 will maintain 12 kV/mm (300 V/mil) dielectric strength for several hours at 400°C.

The exceptional thermal properties of Nomex® 410 are confirmed by more than 50 years of commercial experience.

The thermal conductivity values for Nomex® 410 are similar to those for cellulosic papers, being primarily determined by specific gravity (density). Thus, thinner grades of Nomex® 410 have slightly lower conductivity while thicker grades have higher conductivities. It is important to note that the total system construction may affect the overall thermal conductivity. Therefore, care should be taken when applying individual sheet data to actual situations.

Chemical Stability

The compatibility of Nomex® papers and pressboards with virtually all classes of electrical varnishes and adhesives—polyimides, silicones, epoxies, polyesters, acrylics, phenolics, synthetic rubbers, etc.—as well as other components of electrical equipment, is demonstrated by the many UL-recognized systems based on Nomex® products.

Nomex® papers are also fully compatible, and in wide commercial use, with transformer fluids—mineral oil, silicone oil and other synthetics—and with lubricating oils and refrigerants used in hermetic systems.

Common industrial solvents such as alcohols, ketones, acetone, toluene and xylene have a slight softening and swelling effect on Nomex® 410, similar to that of water. These effects are mainly reversible when the solvent is removed.

Flame Resistance

The Limiting Oxygen Index (LOI) of Nomex® 410 at room temperature ranges between 27% and 32%, depending on thickness and density. At 220°C, the LOI of Nomex® 410 ranges between 22% and 25%. Materials with an LOI above 20.8%--the critical value for combustion in air—will not support combustion.

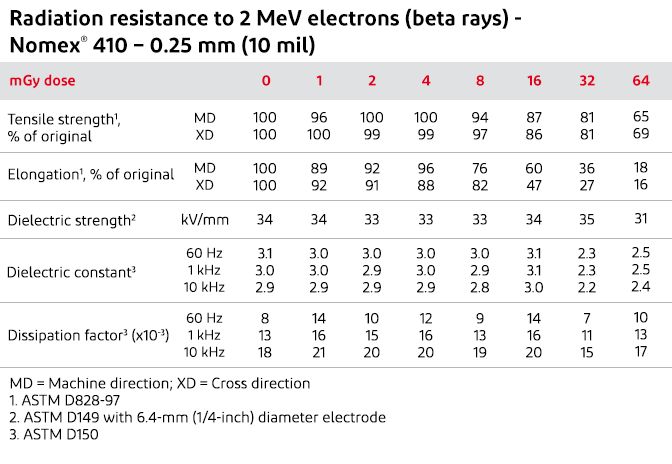

Radiation Resistance

Nomex® 410 is essentially unaffected by 800 megarads (8 Mgy) of ionizing radiation and still retains useful mechanical and electrical properties after eight times this exposure. By comparison, a laminate of polyester film and polyester mat of the same thickness, 100% epoxy-impregnated, crumbled after 800 megarads (8 Mgy). Similar results are seen with exposure to gamma radiation.

The outstanding radiation resistance of Nomex® 410 has led to its use in critical control equipment for nuclear power installations.

The properties in this article are typical or average values and should not be used as specification limits. Unless otherwise noted, all properties were measured in air under “standard” conditions (in equilibrium at 23°C, 50% relative humidity). Note that, like other products of papermaking technology, Nomex® papers have somewhat different properties in the papermaking machine direction (MD) compared to the cross direction (XD). In some applications, it may be necessary to orient the paper in the optimum direction to obtain its maximum potential performance.

Product safety information is available upon request. This information corresponds to our current knowledge on the subject. It is offered solely to provide possible suggestions for your own experimentation. It is not intended, however, to substitute for any testing you may need to conduct to determine for yourself the suitability of our products for your particular purposes. This information may be subject to revision as new knowledge and experience become available. Since we cannot anticipate all variations in actual end-use conditions, DuPont makes no warranties and assumes no liability whatsoever in connection with any use of this information. Nothing in this publication is to be considered as a license to operate under or a recommendation to infringe upon any trademark or patent right.