Setting new standards for performance and economy

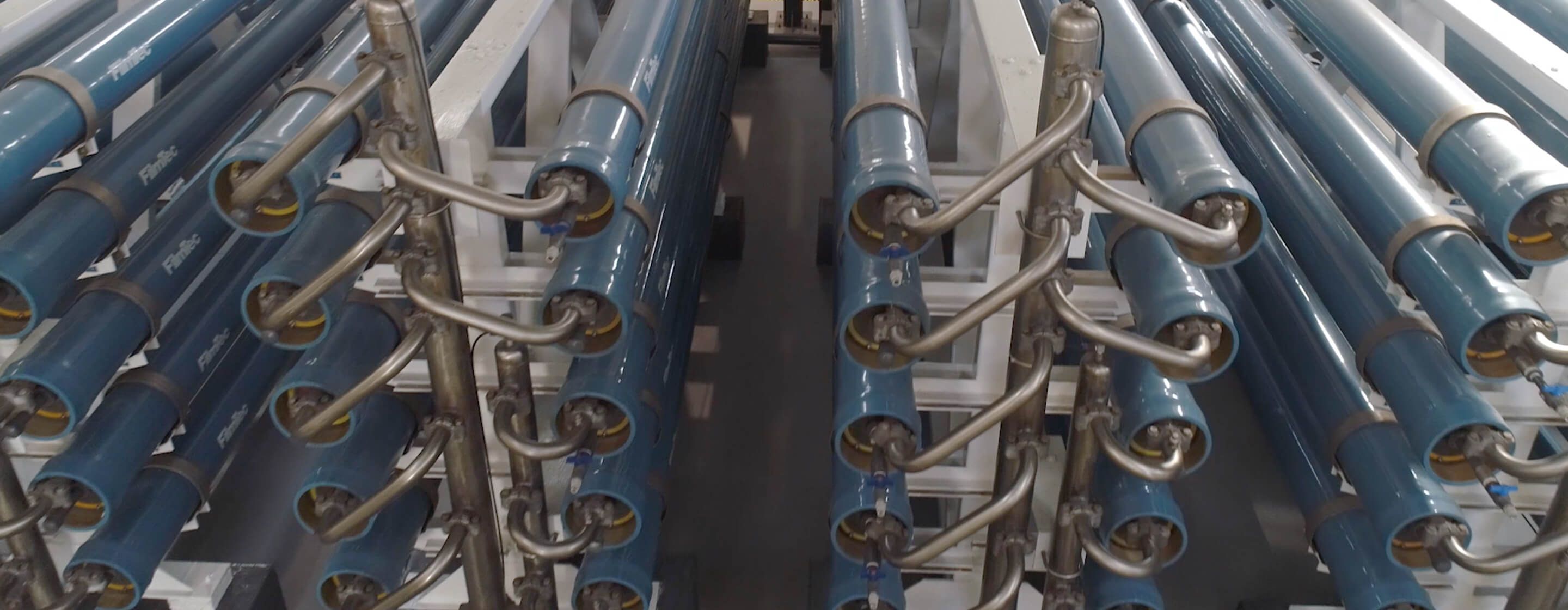

The FilmTec™ portfolio consists of separation-technology products that are highly effective in industrial, municipal, commercial, and consumer water applications.

The new FilmTec™ Prime RO brackish water reverse osmosis elements boost performance to a prime level while reaching an unparallel sustainability impact. Achieve reduced energy by up to 20% while improving the permeate quality by up to 60% with the new brackish water reverses osmosis elements for industrial applications.

Leveraging proven and highly effective technologies, such as reverse osmosis (RO) and nanofiltration (NF), FilmTec™ products reject more dissolved solids and organics, and use less energy to produce permeate, than typical elements.

From use in brackish water purification to specialty separations, elements in the FilmTec™ portfolio achieve high, yet cost-effective, performance through their ability to:

- Tolerate a wide range of operating conditions.

- Operate very efficiently at lower pressures.

- Maintain excellent structural and pH stability.

- Resist bacterial growth.

- Produce excellent membrane flux and salt rejection.

Designed to treat challenging waters and achieve specialty separations

Greater salt rejection and higher productivity

FilmTec™ reverse osmosis membrane elements are very effective at industrial process water treatment. In many industrial systems, RO elements also serve as pretreatment for ion exchange (IX) resin beds. Because of its exceptional properties, FilmTec™ technology can help lower capital investment, reduce operating costs, and allow for greater flexibility for future system expansion.

Portfolio elements that work well for process water treatment include:

- FilmTec™ brackish water elements, which have an unsurpassed high-active membrane surface area that produces 99.5 percent or greater typical salt rejection performance.

- FilmTec™ low-energy brackish water elements, which are designed specifically to meet emerging demand for lower-pressure RO system operation; these elements help reduce operating expense without sacrificing salt rejection or high productivity.

- FilmTec™ reverse osmosis membrane elements that are installed before ion exchange beds, which help reduce demineralizer operating costs dramatically; pretreating water for boiler makeup with these elements removes silica, dissolved solids, and total organic carbon (TOC), extending the life of the resins and lowering chemical regeneration usage, waste handling, and maintenance costs.

- FilmTec™ reverse osmosis membrane elements that are used in double-pass RO systems, which produce high-purity water in a continuous process; for applications with less stringent water-purity requirements, these elements can be used cost-effectively in single-pass RO systems as well.

Greater contamination reduction

Used to rinse integrated circuits in semiconductor manufacturing, ultrapure water requires a rigorous resistivity of 18.2 megohm/cm. The FilmTec™ portfolio includes reverse osmosis membrane elements that greatly reduce the potential for contamination in ultrapure water processing systems.

Other FilmTec™ element advancements include:

- A TOC rinse down to less than 20 ppb in one hour.

- Excellent isopropyl alcohol (IPA) and silica rejection.

- Having been tested and accepted for application in a process where higher feed pH allows higher rejection of weak acid anions, such as boron and silica.

Reliable salt rejection and bacterial resistance

FilmTec™ reverse osmosis membrane elements are used globally to meet the needs of today’s growing drinking-water supply. These elements excel at seawater desalination with consistent reliability, long life, high salt-rejection capability, and resistance to bacterial fouling.

FilmTec™ LE (low-energy) brackish water elements can treat large volumes of water at low operating pressures. Low operating pressures mean reduced operating costs, with maintained high productivity.

FilmTec™ nanofiltration (NF) elements are also used to purify public drinking water in areas where the high level of sodium rejection possible with RO membranes is not needed, but where other salts, such as calcium and magnesium, must be removed. NF membrane softening is a less-expensive alternative compared to lime softening and sodium chloride (NaCl) zeolite softening technologies. Specifically, the FilmTec™ NF270 nanofiltration membrane offers low salt rejection, low energy consumption, and stable performance after repetitive cleaning. These features make it a prime choice for contaminated surface waters.

Predictable performance

FilmTec™ reverse osmosis membrane elements are used in a variety of commercial applications, from restaurants to car washes and hotels to medical and scientific laboratories. They offer highly predictable performance, high salt rejection, and high flow rates.

FilmTec™ elements are available for systems of all sizes and water requirements.

Most FilmTec™ commercial system elements are available shipped either dry or in traditional wet form. Dry elements weigh less, can be stored more easily, and have a longer shelf life than wet elements. Because there are no storage solutions to rinse, dry elements are also easier and take lest time to install.

Highest quality available

Known for their elite brand status, FilmTec™ elements produce high-quality home drinking water, including low-pressure drinking-water elements capable of supplying whole-house and point-of-use water treatment.

FilmTec™ tap water RO elements feature advanced membrane technology and offer outstanding reliability and consistency. Our automated fabrication process allows precise production of every element to tight, predefined specifications.

Like all FilmTec™ reverse osmosis membrane elements, home drinking-water elements are precision fabricated and thoroughly tested to ensure that they provide predictable, trouble-free operation and consistent high performance. They meet a wide range of water volume requirements, from 24 gallons per day to 800 gallons per day. These elements are available to ship dry.

-

Process Water Treatment

Greater salt rejection and higher productivity

FilmTec™ reverse osmosis membrane elements are very effective at industrial process water treatment. In many industrial systems, RO elements also serve as pretreatment for ion exchange (IX) resin beds. Because of its exceptional properties, FilmTec™ technology can help lower capital investment, reduce operating costs, and allow for greater flexibility for future system expansion.

Portfolio elements that work well for process water treatment include:

- FilmTec™ brackish water elements, which have an unsurpassed high-active membrane surface area that produces 99.5 percent or greater typical salt rejection performance.

- FilmTec™ low-energy brackish water elements, which are designed specifically to meet emerging demand for lower-pressure RO system operation; these elements help reduce operating expense without sacrificing salt rejection or high productivity.

- FilmTec™ reverse osmosis membrane elements that are installed before ion exchange beds, which help reduce demineralizer operating costs dramatically; pretreating water for boiler makeup with these elements removes silica, dissolved solids, and total organic carbon (TOC), extending the life of the resins and lowering chemical regeneration usage, waste handling, and maintenance costs.

- FilmTec™ reverse osmosis membrane elements that are used in double-pass RO systems, which produce high-purity water in a continuous process; for applications with less stringent water-purity requirements, these elements can be used cost-effectively in single-pass RO systems as well.

-

Ultrapure Water

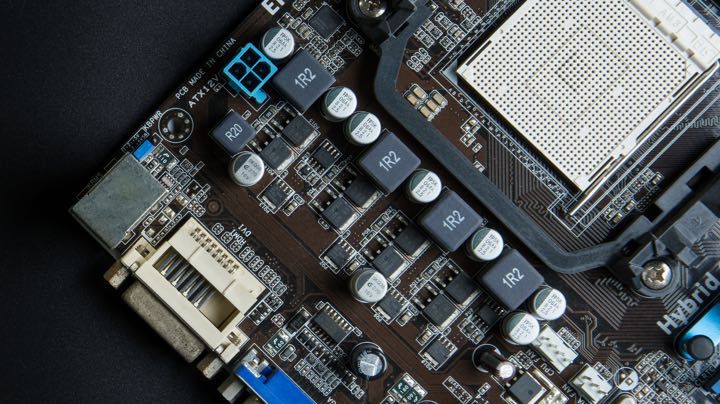

Greater contamination reduction

Used to rinse integrated circuits in semiconductor manufacturing, ultrapure water requires a rigorous resistivity of 18.2 megohm/cm. The FilmTec™ portfolio includes reverse osmosis membrane elements that greatly reduce the potential for contamination in ultrapure water processing systems.

Other FilmTec™ element advancements include:

- A TOC rinse down to less than 20 ppb in one hour.

- Excellent isopropyl alcohol (IPA) and silica rejection.

- Having been tested and accepted for application in a process where higher feed pH allows higher rejection of weak acid anions, such as boron and silica.

-

Municipal Water

Reliable salt rejection and bacterial resistance

FilmTec™ reverse osmosis membrane elements are used globally to meet the needs of today’s growing drinking-water supply. These elements excel at seawater desalination with consistent reliability, long life, high salt-rejection capability, and resistance to bacterial fouling.

FilmTec™ LE (low-energy) brackish water elements can treat large volumes of water at low operating pressures. Low operating pressures mean reduced operating costs, with maintained high productivity.

FilmTec™ nanofiltration (NF) elements are also used to purify public drinking water in areas where the high level of sodium rejection possible with RO membranes is not needed, but where other salts, such as calcium and magnesium, must be removed. NF membrane softening is a less-expensive alternative compared to lime softening and sodium chloride (NaCl) zeolite softening technologies. Specifically, the FilmTec™ NF270 nanofiltration membrane offers low salt rejection, low energy consumption, and stable performance after repetitive cleaning. These features make it a prime choice for contaminated surface waters.

-

Commercial Water

Predictable performance

FilmTec™ reverse osmosis membrane elements are used in a variety of commercial applications, from restaurants to car washes and hotels to medical and scientific laboratories. They offer highly predictable performance, high salt rejection, and high flow rates.

FilmTec™ elements are available for systems of all sizes and water requirements.

Most FilmTec™ commercial system elements are available shipped either dry or in traditional wet form. Dry elements weigh less, can be stored more easily, and have a longer shelf life than wet elements. Because there are no storage solutions to rinse, dry elements are also easier and take lest time to install.

-

Home Drinking Water

Highest quality available

Known for their elite brand status, FilmTec™ elements produce high-quality home drinking water, including low-pressure drinking-water elements capable of supplying whole-house and point-of-use water treatment.

FilmTec™ tap water RO elements feature advanced membrane technology and offer outstanding reliability and consistency. Our automated fabrication process allows precise production of every element to tight, predefined specifications.

Like all FilmTec™ reverse osmosis membrane elements, home drinking-water elements are precision fabricated and thoroughly tested to ensure that they provide predictable, trouble-free operation and consistent high performance. They meet a wide range of water volume requirements, from 24 gallons per day to 800 gallons per day. These elements are available to ship dry.

Precision fabrication for the ultimate in quality

Fabricated in our ISO 9002 certified facility, FilmTec™ reverse osmosis membrane elements are produced using the industry’s most advanced precision manufacturing technology. With high-quality raw materials,

these elements help achieve high strength, durability, and consistency.

We thoroughly test our elements to ensure that they provide predictable, trouble-free operation. Our quality control process includes visual and vacuum testing of glue lines and wet testing to confirm rejection and flow performance.

As a result, FilmTec™ elements exhibit very few element-to-element differences. Each of our wet elements is packaged with a storage solution in an oxygen barrier bag before shipment to minimize the chance of biological contamination.

We assure the quality and performance of FilmTec™ elements with a robust three-year limited warranty and extensive service and support.

Find FilmTec™ products

View a list of our industry-leading FilmTec™ products, including product data sheets.

Related technologies

Our technologies provide industry-leading, long-lasting, and cost-effective solutions. Learn more about the technologies used in FilmTec™ products.

NF is a pressure-driven separation process positioned between reverse osmosis and ultrafiltration used to treat color and pesticides, and to partially soften the water.

RO is a pressure-driven separation process that reduces the smallest of solute particles and treats most ions and large molecules in the water.

Related industries

Our technologies provide premium solutions for a broad range of industries. The following industries benefit from the FilmTec™ portfolio of products.

We help offices, schools, hospitals, hotels, and universities enhance their facilities with our water-treatment solutions.

We help everyone’s favorite foods and beverages taste better with advanced separations of sugars, dairy streams, and other nutritional ingredients.

Our technologies and solutions are designed to help you overcome water challenges to produce your desired quantity and quality of industrial utility water.

We develop best-in-class technologies, accompanied by an advanced product portfolio of solutions, to address your crucial wastewater challenges.

We enable the production of some of today’s most popular technologies by facilitating ultrapure water and effective water reuse.

We help ensure a steady flow of clean, safe drinking water into local communities with our water-treatment solutions.

We help energy companies improve operational efficiency with specialized water treatment and wastewater reuse.

We enable the smooth and safe operation of power plants through innovative water-treatment and wastewater reuse.

We help improve the safety and quality of drinking water in homes with exceptional water treatment.

Related resources

See what’s possible

Ask how we can help your industry or market with our leading FilmTec™ portfolio of reverse osmosis membrane elements.