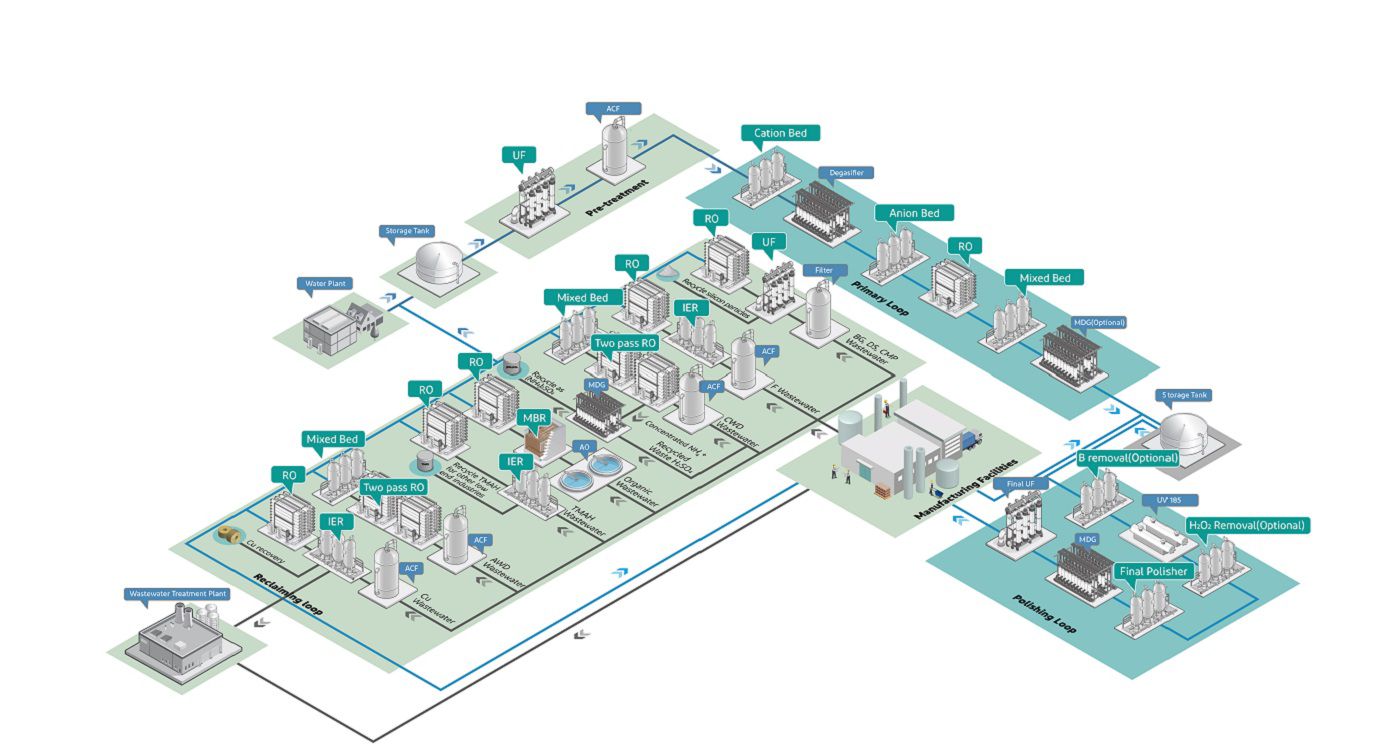

Multi-tech solutions that enable ultrapure water preparation, minimum liquid discharge, and optimum waste resource recovery

Ultrapure water (UPW) is a vital resource in the fabrication of microelectronic devices and components, such as semiconductor wafers, flat panel displays, and solar photovoltaic cells. The global industry is facing stricter wastewater discharge standards and more demanding sustainability targets, in part due to increasing regional water scarcity and increasing raw material costs. This is compelling end-users to increase their reclamation of wastewater for the reuse and recycling of purified water and other precious resources through minimum- or zero-liquid discharge (MLD/ZLD) strategies.

DuPont Water Solutions is a trusted and valued partner for end-users, original equipment manufacturers (OEMs), and service companies around the world. Our experience and variety of solutions make us the perfect partner for the preparation of UPW, wastewater reuse, resource recovery, and purification through innovative multi-tech solutions with ultrafiltration (UF), membrane bioreactors (MBR), reverse osmosis (RO), and ion exchange resin (IER) technologies.

Multi-tech Solutions for Microelectronics Fabrication

Learn more about our solutions in the industry.

Protection for the entire water purification system

The removal of hardness or large particles, such as suspended solids and colloids, prior to primary lines are key steps to guarantee the best performance of downstream demineralization treatments.

Pretreatment with Ultrafiltration (UF)

DuPont UF technologies have a proven track record in enhancing overall system stability and productivity by reliably removing suspended solids, colloids, and algae, thus protecting downstream water purification steps, such as RO and IER systems. With the integration of heritage DuPont™, inge®, and MEMCOR™ technologies, DuPont™ IntegraTec™ provides the widest variety of UF products including inside-out and outside-in configuration, PES and PVDF components, pressurized and submerged UF, individual modules, and racks. With this multitude of solution offerings, DuPont can provide the most suitable UF products to ensure superior system stability while reducing energy and chemical consumption.

- DuPont™ IntegraTec™ XP 77 IG: PVDF, outside-in UF module, 77m2 surface area

- DuPont™ IntegraTec™ MB PRO 95: PES, inside-out UF module, 95m2 surface area

- DuPont™ IntegraTec™ MB 80: PES, inside-out UF module, 80m2 surface area

Softening with AmberLite™ Ion Exchange Resins ahead of Reverse Osmosis (RO) Systems

DuPont’s softening and dealkalization Ion Exchange Resins (IER) remove the hardness traces to protect downstream water purification steps by reducing the scaling potential and allow for increased water recovery of RO systems. DuPont offers a variety of both strong acid cation (SAC) and weak acid cation (WAC) ion exchange resins to suit the requirements of your overall water treatment system design.

- AmberLite™ HPR1200 Na: Polyvalent, high-capacity, uniform particle size, SAC to prepare high purity demineralized water

- AmberLite™ HPR8300 H: Very high-capacity, uniform particle size, WAC to remove alkalinity and reduce potential fouling problems.

- AmberLite™ MAC-3 H: High-capacity, food-grade WAC to produce pure dealkalinized water immediately from the first service run.

Learn more about our UPW pretreatment products by visiting our product finder.

Removal of dissolved impurities to reach pre-ultrapure water quality

Demineralization with Amber Series ion exchange resins (IERs)

The use of IER for demineralization is a well-establish practice in microelectronics and semiconductor fabrication. DuPont has developed and selected a special range of IERs to reliably produce high-quality water immediately ahead of reverse osmosis (RO) units.

- AmberLite™ MAC-3 H: High-capacity, food-grade WAC to produce pure dealkalinized water immediately from the first service run.

- AmberLite™ HPR8300 H: Very high-capacity, uniform particle size, WAC to remove alkalinity and reduce potential fouling problems.

- AmberTec™ UP9600: High-purity, uniform particle size, macroporous WBA exchanger specifically designed for stratified bed systems and reverse-flow systems to produce pure dealkalinized water immediately from the first service run.

- AmberTec™ UP9700: High-purity, uniform particle size, macroporous WBA exchanger specifically designed for floating bed systems requiring low pressure drop to produce pure dealkalinized water immediately from the first service run.

- AmberLite™ HPR4200 OH: Uniform particle size SBA resin for stratified bed systems and reverse flow units requiring low pressure drop.

- AmberLite™ HPR4800 OH: Uniform particle size SBA resin for co-flow and reverse flow systems requiring high kinetics.

Removal of total organic carbon (TOC) and dissolved salts with FilmTec™ Reverse Osmosis (RO)

FilmTec™ is the inventor and industry leader of thin-film composite reverse osmosis membranes. FilmTec™ RO is renowned for its consistently high quality and robust design, creating an enhanced value over the entire lifetime. DuPont offers a variety of RO products to meet specific needs on TOC and total dissolved (TDS) rejection, energy consumption, cleanliness, and anti-fouling capability.

- FilmTec™ SG30LE PRO-440: Semiconductor-grade module with high organics rejection, reduced energy consumption, and anti-fouling module design.

- FilmTec™ SG30-400/34i: Semiconductor-grade module with higher organics rejection and enhanced fouling protection

- FilmTec™ BW30XHR PRO-440: Exceptional permeate quality with excellent silica, boron, nitrate, TOC, and ammonium rejection.

- FilmTec™ ECO PRO-440: Lower energy consumption and high TDS rejection. Available with standard or iLEC™ interconnecting endcaps.

- FilmTec™ Fortilife™ CR100(i): High TDS and TOC rejection with patented anti-biofouling module design. Available with standard or iLEC™ interconnecting endcaps.

Mixed bed demineralization with AmberTec™ ion exchange resins (IER)

- AmberTec™ UP1400 H and AmberTec™ UP4000 OH: High-capacity, uniform particle size strong acid and strong base for self-prepared polishing mixed beds.

- AmberTec™ UP650 H and AmberTec™ UP550 OH: Polyvalent, high-capacity combination for polishing and regenerable mixed beds

- AmberTec™ UP252 H and AmberTec™ UP900 OH: Macroporous combination for regenerable mixed beds allowing for high visibility prior to the injection of regeneration chemicals.

Learn more about our UPW primary loop products by visiting our product finder.

Elimination of trace contaminants for ultra-pure water production to meet fabrication demands

AmberTec™ ion exchange and mixed bed resins for final polishing

Selecting a suitable final polishing mixed bed resin is key to meeting stringent production requirements for resistivity, metal contaminant concentration, and total organic carbon (TOC). DuPont AmberTec™ final polishing mixed bed resins are widely recognized and a trusted solution due to their consistent and reliable performance.

- AmberTec™ UP6150 H/OH: Uniform particle size mixed bed with proven performance in display panel and other similar industries.

- AmberTec™ UP6040 H/OH: Uniform particle size mixed bed with proven performance on low TOC and metal leaching for semiconductor fabrication.

- AmberTec™ UP6060 H/OH: Uniform particle size mixed bed with extraordinarily low metal and TOC leaching for high-end semiconductor fabrication.

Removal of boron with AmberTec™ UP7530 boron-selective ion exchange resin

AmberTec™ UP7530 is a semiconductor-grade, boron-selective ion exchange resin with low TOC, high working capacity, and uniform particle size. It is specifically designed for systems with high boron contamination levels or stringent process requirements.

Reduction of hydrogen peroxide with AmberTec™ UP4000Pd OH ion exchange resin

AmberTec™ UP4000Pd OH is a palladium-doped strong base anion exchange resin. This semiconductor-grade resin with exceptionally high space velocity is specifically designed to reduce trace amounts of H2O2 generated as a by-product of up-stream UV oxidation.

Learn more about our UPW polishing loop products by visiting our product finder.

Recycle, Reuse, and Reduce - Wastewater solutions to optimize consumption and minimize discharge

The manufacturing of microelectronic devices and components is a water-intensive process. Reclamation of wastewater from a variety of processes is an achievable means of conserving water and other precious resources. DuPont has developed a variety of wastewater solutions through the 3R (Recycle, Reuse, Reduce) mission to: Recycle precious resources; Reuse water in production facilities; and Reduce the discharge of hazardous pollutants.

Acidic and caustic wastewater reuse with FilmTec™ reverse osmosis (RO)

For acidic and caustic wastewater, which is mainly rinse water from the production lines, FilmTec™ BW30XHR PRO-440 and FilmTec™ ECO PRO-440 can be used to produce a high quality, low TDS permeate water stream thanks to the high rejection of weak ions, such as NH4+.

Recycle Tetra-methyl ammonium hydroxide (TMAH) with AmberLite™ ion exchange resins

DuPont™ AmberLite™ series, high-capacity weak acid cation (WAC) resins are a reliable and proven solution to recover TMAH from process streams.

Recycle precious metals with Amber series ion exchange resins

AmberSep™ IRC748 UPS, a chelating resin, and AmberLite™ HPR2000 H, a strong acid cation (SAC), are two valuable options to recover copper (Cu) from wastewater.

Removal of fine silicon particles with DuPont IntegraTec™ UF to increase water recovery

DuPont™ IntegraTec™ XP and DuPont™ IntegraTec™ MB 40 ultrafiltration modules are proven effective at reducing fine silicon particles present in back grinding (BG), dicing saw (DS), and chemical mechanical polishing (CMP) wastewater, increasing water recovery capability.

Wastewater treatment with MemPulse® membrane bioreactor (MBR) and FilmTec™ Fortilife™ reverse osmosis (RO) modules for water reuse

DuPont™ MemPulse® MBR can be used to treat wastewater by first removing dissolved and suspended organic matter with minimal additional chemical requirement and compact footprint. FilmTec™ Fortilife™ CR100 and CR200 can further reduce the total dissolved solids (TDS) and total organic carbon (TOC) content, providing a high quality permeate water for reuse in the manufacturing process.

Learn more about our microelectronics reclaming loop products by visiting our product finder.

-

Pretreatment

Protection for the entire water purification system

The removal of hardness or large particles, such as suspended solids and colloids, prior to primary lines are key steps to guarantee the best performance of downstream demineralization treatments.

Pretreatment with Ultrafiltration (UF)

DuPont UF technologies have a proven track record in enhancing overall system stability and productivity by reliably removing suspended solids, colloids, and algae, thus protecting downstream water purification steps, such as RO and IER systems. With the integration of heritage DuPont™, inge®, and MEMCOR™ technologies, DuPont™ IntegraTec™ provides the widest variety of UF products including inside-out and outside-in configuration, PES and PVDF components, pressurized and submerged UF, individual modules, and racks. With this multitude of solution offerings, DuPont can provide the most suitable UF products to ensure superior system stability while reducing energy and chemical consumption.

- DuPont™ IntegraTec™ XP 77 IG: PVDF, outside-in UF module, 77m2 surface area

- DuPont™ IntegraTec™ MB PRO 95: PES, inside-out UF module, 95m2 surface area

- DuPont™ IntegraTec™ MB 80: PES, inside-out UF module, 80m2 surface area

Softening with AmberLite™ Ion Exchange Resins ahead of Reverse Osmosis (RO) Systems

DuPont’s softening and dealkalization Ion Exchange Resins (IER) remove the hardness traces to protect downstream water purification steps by reducing the scaling potential and allow for increased water recovery of RO systems. DuPont offers a variety of both strong acid cation (SAC) and weak acid cation (WAC) ion exchange resins to suit the requirements of your overall water treatment system design.

- AmberLite™ HPR1200 Na: Polyvalent, high-capacity, uniform particle size, SAC to prepare high purity demineralized water

- AmberLite™ HPR8300 H: Very high-capacity, uniform particle size, WAC to remove alkalinity and reduce potential fouling problems.

- AmberLite™ MAC-3 H: High-capacity, food-grade WAC to produce pure dealkalinized water immediately from the first service run.

Learn more about our UPW pretreatment products by visiting our product finder.

-

Primary Loop - Demineralization

Removal of dissolved impurities to reach pre-ultrapure water quality

Demineralization with Amber Series ion exchange resins (IERs)

The use of IER for demineralization is a well-establish practice in microelectronics and semiconductor fabrication. DuPont has developed and selected a special range of IERs to reliably produce high-quality water immediately ahead of reverse osmosis (RO) units.

- AmberLite™ MAC-3 H: High-capacity, food-grade WAC to produce pure dealkalinized water immediately from the first service run.

- AmberLite™ HPR8300 H: Very high-capacity, uniform particle size, WAC to remove alkalinity and reduce potential fouling problems.

- AmberTec™ UP9600: High-purity, uniform particle size, macroporous WBA exchanger specifically designed for stratified bed systems and reverse-flow systems to produce pure dealkalinized water immediately from the first service run.

- AmberTec™ UP9700: High-purity, uniform particle size, macroporous WBA exchanger specifically designed for floating bed systems requiring low pressure drop to produce pure dealkalinized water immediately from the first service run.

- AmberLite™ HPR4200 OH: Uniform particle size SBA resin for stratified bed systems and reverse flow units requiring low pressure drop.

- AmberLite™ HPR4800 OH: Uniform particle size SBA resin for co-flow and reverse flow systems requiring high kinetics.

Removal of total organic carbon (TOC) and dissolved salts with FilmTec™ Reverse Osmosis (RO)

FilmTec™ is the inventor and industry leader of thin-film composite reverse osmosis membranes. FilmTec™ RO is renowned for its consistently high quality and robust design, creating an enhanced value over the entire lifetime. DuPont offers a variety of RO products to meet specific needs on TOC and total dissolved (TDS) rejection, energy consumption, cleanliness, and anti-fouling capability.

- FilmTec™ SG30LE PRO-440: Semiconductor-grade module with high organics rejection, reduced energy consumption, and anti-fouling module design.

- FilmTec™ SG30-400/34i: Semiconductor-grade module with higher organics rejection and enhanced fouling protection

- FilmTec™ BW30XHR PRO-440: Exceptional permeate quality with excellent silica, boron, nitrate, TOC, and ammonium rejection.

- FilmTec™ ECO PRO-440: Lower energy consumption and high TDS rejection. Available with standard or iLEC™ interconnecting endcaps.

- FilmTec™ Fortilife™ CR100(i): High TDS and TOC rejection with patented anti-biofouling module design. Available with standard or iLEC™ interconnecting endcaps.

Mixed bed demineralization with AmberTec™ ion exchange resins (IER)

- AmberTec™ UP1400 H and AmberTec™ UP4000 OH: High-capacity, uniform particle size strong acid and strong base for self-prepared polishing mixed beds.

- AmberTec™ UP650 H and AmberTec™ UP550 OH: Polyvalent, high-capacity combination for polishing and regenerable mixed beds

- AmberTec™ UP252 H and AmberTec™ UP900 OH: Macroporous combination for regenerable mixed beds allowing for high visibility prior to the injection of regeneration chemicals.

Learn more about our UPW primary loop products by visiting our product finder.

-

Polishing Loop - UPW Production

Elimination of trace contaminants for ultra-pure water production to meet fabrication demands

AmberTec™ ion exchange and mixed bed resins for final polishing

Selecting a suitable final polishing mixed bed resin is key to meeting stringent production requirements for resistivity, metal contaminant concentration, and total organic carbon (TOC). DuPont AmberTec™ final polishing mixed bed resins are widely recognized and a trusted solution due to their consistent and reliable performance.

- AmberTec™ UP6150 H/OH: Uniform particle size mixed bed with proven performance in display panel and other similar industries.

- AmberTec™ UP6040 H/OH: Uniform particle size mixed bed with proven performance on low TOC and metal leaching for semiconductor fabrication.

- AmberTec™ UP6060 H/OH: Uniform particle size mixed bed with extraordinarily low metal and TOC leaching for high-end semiconductor fabrication.

Removal of boron with AmberTec™ UP7530 boron-selective ion exchange resin

AmberTec™ UP7530 is a semiconductor-grade, boron-selective ion exchange resin with low TOC, high working capacity, and uniform particle size. It is specifically designed for systems with high boron contamination levels or stringent process requirements.

Reduction of hydrogen peroxide with AmberTec™ UP4000Pd OH ion exchange resin

AmberTec™ UP4000Pd OH is a palladium-doped strong base anion exchange resin. This semiconductor-grade resin with exceptionally high space velocity is specifically designed to reduce trace amounts of H2O2 generated as a by-product of up-stream UV oxidation.

Learn more about our UPW polishing loop products by visiting our product finder.

-

Reclaiming Loop - Wastewater Treatment

Recycle, Reuse, and Reduce - Wastewater solutions to optimize consumption and minimize discharge

The manufacturing of microelectronic devices and components is a water-intensive process. Reclamation of wastewater from a variety of processes is an achievable means of conserving water and other precious resources. DuPont has developed a variety of wastewater solutions through the 3R (Recycle, Reuse, Reduce) mission to: Recycle precious resources; Reuse water in production facilities; and Reduce the discharge of hazardous pollutants.

Acidic and caustic wastewater reuse with FilmTec™ reverse osmosis (RO)

For acidic and caustic wastewater, which is mainly rinse water from the production lines, FilmTec™ BW30XHR PRO-440 and FilmTec™ ECO PRO-440 can be used to produce a high quality, low TDS permeate water stream thanks to the high rejection of weak ions, such as NH4+.

Recycle Tetra-methyl ammonium hydroxide (TMAH) with AmberLite™ ion exchange resins

DuPont™ AmberLite™ series, high-capacity weak acid cation (WAC) resins are a reliable and proven solution to recover TMAH from process streams.

Recycle precious metals with Amber series ion exchange resins

AmberSep™ IRC748 UPS, a chelating resin, and AmberLite™ HPR2000 H, a strong acid cation (SAC), are two valuable options to recover copper (Cu) from wastewater.

Removal of fine silicon particles with DuPont IntegraTec™ UF to increase water recovery

DuPont™ IntegraTec™ XP and DuPont™ IntegraTec™ MB 40 ultrafiltration modules are proven effective at reducing fine silicon particles present in back grinding (BG), dicing saw (DS), and chemical mechanical polishing (CMP) wastewater, increasing water recovery capability.

Wastewater treatment with MemPulse® membrane bioreactor (MBR) and FilmTec™ Fortilife™ reverse osmosis (RO) modules for water reuse

DuPont™ MemPulse® MBR can be used to treat wastewater by first removing dissolved and suspended organic matter with minimal additional chemical requirement and compact footprint. FilmTec™ Fortilife™ CR100 and CR200 can further reduce the total dissolved solids (TDS) and total organic carbon (TOC) content, providing a high quality permeate water for reuse in the manufacturing process.

Learn more about our microelectronics reclaming loop products by visiting our product finder.

Find products for the microelectronics industry

View a list of products suitable for the production of ultrapure water in microelectronic manufacturing.

Related resources

See what’s possible

Ask how we can help you achieve the optimal microelectronics manufacturing process.