The peace of mind that comes from working with trusted partners

Ultrafiltration (UF) is a purification process that separates particulate matter from soluble compounds using an ultrafine membrane media. Ultrafiltration is an excellent separation technology for desalination pretreatment, reverse osmosis pretreatment, and wastewater reclamation, as well as for producing potable water.

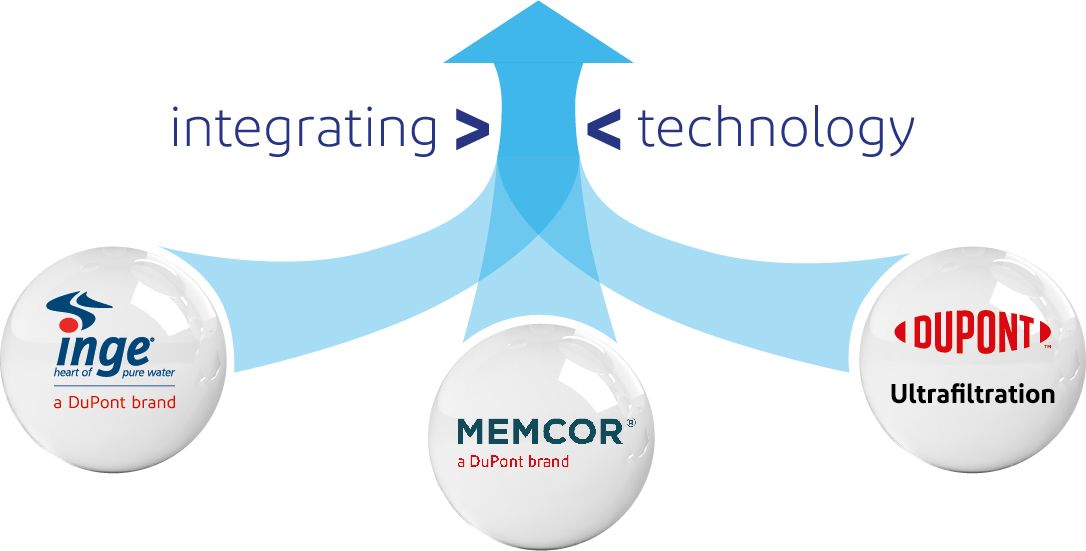

At DuPont, we created DuPont™ IntegraTec™, an Integrated Ultrafiltration Technology Portfolio, that combines three industry leading brands – inge® , MEMCOR® and DuPont™ - to deliver over 35 years of experience and knowledge to the industry.

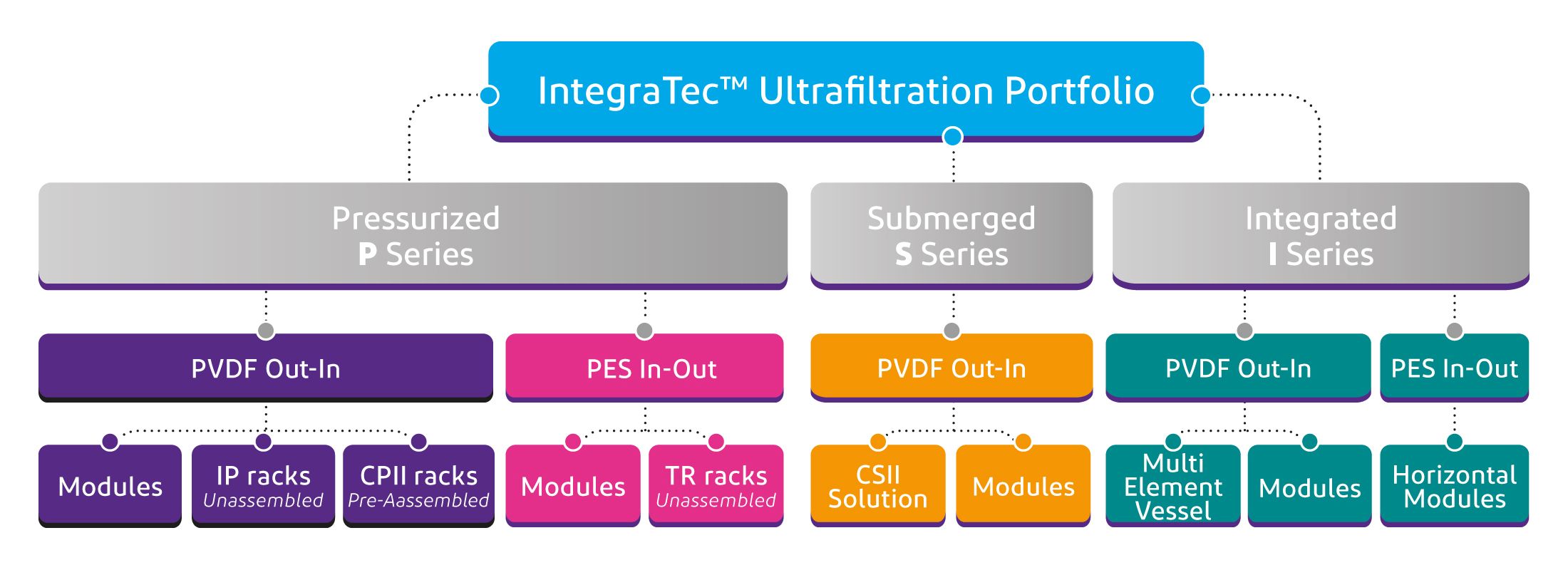

Fusing together three immensely successful brands creates something far stronger than the sum of its parts. Through our multi-element UF, submerged UF, pressurized UF, and UF module components, we deliver the solution you need where you need it.

A closer look

Superior to sand filters and traditional media filtration

As with most conventional filtration methods, sand filters and media filtration require consistent raw water quality to deliver quality effluent, which is not always possible. They also don't provide an absolute barrier. Traditional media filters typically remove particles to down to about 5 microns.

Ultrafiltration (UF), however, does not suffer from those limitations. This technology uses an ultrafiltration membrane barrier to exclude particles 0.02 to 0.05 microns, including bacteria, viruses, and colloids, meeting increasingly stringent water-quality standards around the world, and providing a stable, reliable, and consistent water quality.

UF offers:

- High and consistent product quality measured by turbidity (NTU) or silt density index (SDI).

- Tolerance to feedwater quality upsets.

- No use of pretreatment chemicals (polymer, coagulant, pH adjustment) and associated costs for sludge disposal.

- Small footprint and less weight than media filters.

When used as a pretreatment for reverse osmosis (RO) , UF also helps reduce fouling of the RO membranes, which can lead to:

- Reduced chemical cleaning frequency and consequently, lower operating costs and downtime.

- The potential to operate RO at higher flux, with fewer membranes and vessels — leading to lower capital cost for the RO system.

Rejecting particles, colloids, and macromolecules

In ultrafiltration, water and low-molecular-weight substances are passed through an ultrafine membrane by the application of pressure to the system; flow through the membrane is achieved by applying a pressure gradient between the outer and inner walls of the membrane structure. Feed pressure is from 4 to 100 psig (typically < 30) and transmembrane pressure is generally <14 psig.

Ultrafiltration membranes have pore sizes in the range of 0.02 – 0.05 microns, which contributes to the production of high-quality water; the pore-size range means that the purification process is characterized by a high removal capability of bacteria, viruses, colloids, and silt. The process, however, does not reject particles smaller than the pores, such as dissolved salts or organics; nor does it reject other species such as true color, taste, and odor.

Ultrafiltration membranes have a service life of three to seven years (and potentially longer). They are commercially available in hollow fiber, tubular, plate, and frame, as well as spiral wound configurations.

High-filtration performance, high recovery, and energy savings

Our ultrafiltration modules are made with high-strength, hollow-fiber ultrafiltration membranes that offer the following features:

- 0.03 μm nominal pore diameter to facilitate high-removal capability for bacteria, viruses, and particulates, including colloids.

- PVDF polymeric hollow fibers for high strength and chemical resistance.

- Hydrophilic PVDF fibers for easy cleaning and wettability to help maintain long-term performance.

- Outside-in flow configuration for high tolerance to feed solids and the use of air scour cleaning.

- U-PVC housings, which eliminate the need for pressure vessels and are resistant to UV light.

The outside-in flow configuration is tolerant of wide-ranging feed water qualities and allows air scour cleaning. The dead-end flow offers higher recovery and energy savings. The pressurized vertical shell-and-tube design eliminates the need for separate pressure vessels and allows easy removal of air from cleaning along with integrity testing steps.

The hollow fiber ultrafiltration membranes are 1.3 mm outside diameter and 0.7 mm inside diameter and are made from PVDF polymer. The fibers are strong due to a combination of PVDF polymer, an asymmetric membrane with smaller pores in the active filtration area, and a high porosity substructure. PVDF membranes offer high chemical resistance (e.g., resistance to chlorine) and are tolerant to temperatures of 40°C.

-

What Is UF?

Superior to sand filters and traditional media filtration

As with most conventional filtration methods, sand filters and media filtration require consistent raw water quality to deliver quality effluent, which is not always possible. They also don't provide an absolute barrier. Traditional media filters typically remove particles to down to about 5 microns.

Ultrafiltration (UF), however, does not suffer from those limitations. This technology uses an ultrafiltration membrane barrier to exclude particles 0.02 to 0.05 microns, including bacteria, viruses, and colloids, meeting increasingly stringent water-quality standards around the world, and providing a stable, reliable, and consistent water quality.

UF offers:

- High and consistent product quality measured by turbidity (NTU) or silt density index (SDI).

- Tolerance to feedwater quality upsets.

- No use of pretreatment chemicals (polymer, coagulant, pH adjustment) and associated costs for sludge disposal.

- Small footprint and less weight than media filters.

When used as a pretreatment for reverse osmosis (RO) , UF also helps reduce fouling of the RO membranes, which can lead to:

- Reduced chemical cleaning frequency and consequently, lower operating costs and downtime.

- The potential to operate RO at higher flux, with fewer membranes and vessels — leading to lower capital cost for the RO system.

-

UF Technology Basics

Rejecting particles, colloids, and macromolecules

In ultrafiltration, water and low-molecular-weight substances are passed through an ultrafine membrane by the application of pressure to the system; flow through the membrane is achieved by applying a pressure gradient between the outer and inner walls of the membrane structure. Feed pressure is from 4 to 100 psig (typically < 30) and transmembrane pressure is generally <14 psig.

Ultrafiltration membranes have pore sizes in the range of 0.02 – 0.05 microns, which contributes to the production of high-quality water; the pore-size range means that the purification process is characterized by a high removal capability of bacteria, viruses, colloids, and silt. The process, however, does not reject particles smaller than the pores, such as dissolved salts or organics; nor does it reject other species such as true color, taste, and odor.

Ultrafiltration membranes have a service life of three to seven years (and potentially longer). They are commercially available in hollow fiber, tubular, plate, and frame, as well as spiral wound configurations.

-

Hollow Fiber Technology

High-filtration performance, high recovery, and energy savings

Our ultrafiltration modules are made with high-strength, hollow-fiber ultrafiltration membranes that offer the following features:

- 0.03 μm nominal pore diameter to facilitate high-removal capability for bacteria, viruses, and particulates, including colloids.

- PVDF polymeric hollow fibers for high strength and chemical resistance.

- Hydrophilic PVDF fibers for easy cleaning and wettability to help maintain long-term performance.

- Outside-in flow configuration for high tolerance to feed solids and the use of air scour cleaning.

- U-PVC housings, which eliminate the need for pressure vessels and are resistant to UV light.

The outside-in flow configuration is tolerant of wide-ranging feed water qualities and allows air scour cleaning. The dead-end flow offers higher recovery and energy savings. The pressurized vertical shell-and-tube design eliminates the need for separate pressure vessels and allows easy removal of air from cleaning along with integrity testing steps.The hollow fiber ultrafiltration membranes are 1.3 mm outside diameter and 0.7 mm inside diameter and are made from PVDF polymer. The fibers are strong due to a combination of PVDF polymer, an asymmetric membrane with smaller pores in the active filtration area, and a high porosity substructure. PVDF membranes offer high chemical resistance (e.g., resistance to chlorine) and are tolerant to temperatures of 40°C.

Why choose DuPont™ IntegraTec™ Ultrafiltration solutions?

- Deep capabilities and advanced expertise

- Dedicated to customer success

- One-stop shop for multiple solutions

- Proven capabilities to bring the solution you need where you need it

- Expertise beyond the product

- Solving various challenges with membrane excellence

- Reliable and durable range of module and rack configurations

- World class UF manufacturing and quality

Selected UF references around the globe

Find ultrafiltration products

View a list of our industry-leading ultrafiltration products.

Related industries

Our technologies provide premium solutions for a broad range of industries. Learn more about the industries that depend on ultrafiltration.

Our technologies and solutions are designed to help you overcome water challenges to produce your desired quantity and quality of industrial utility water.

We develop best-in-class technologies, accompanied by an advanced product portfolio of solutions, to address your crucial wastewater challenges.

We help ensure a steady flow of clean, safe drinking water into local communities with our water-treatment solutions.

We provide high-quality and durable solutions to the seawater reverse osmosis (SWRO) system to last the lifecycle of operations.

We enable the production of some of today’s most popular technologies by facilitating ultrapure water and effective water reuse.

We help energy companies improve operational efficiency with specialized water treatment and wastewater reuse.

We help offices, schools, hospitals, hotels, and universities enhance their facilities with our water-treatment solutions.

We help improve the safety and quality of drinking water in homes with exceptional water treatment.

Related resources

See what’s possible

Let us help you choose the most suitable solution for your specific needs.